Drilling and Tapping Machine Manufacturers in Pune – Technowings Automation

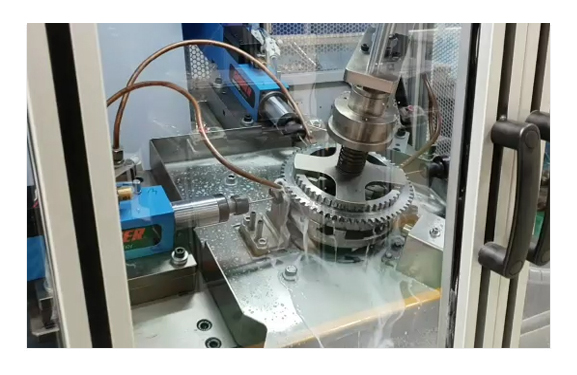

Technowings Automation, a former drilling and tapping machine manufacturers, suppliers and exporters in Pune. We are providing the best drilling and tapping machines, which are usually made for drilling and tapping holes into objects such as metal, pipes and other materials.

We offer this machine in a variety of multiple types as per requirements from various industries or applications. The new technological updates, such as automatic tool changers and high-speed tapping and drilling in our drilling machines, are helping to increase the performance of every unit. Let’s check out its multiple types, benefits and applications one by one!

The multiple types of drilling and tapping machine manufacturer that we offer:

As a former drilling and tapping machine suppliers and exporters in Pune, we have used strong quality material in all types of drilling machines, which gives higher performance. Here we have listed down some types, such as:

- Magnetic Drilling Machine: These are usually used for drilling holes in large, stationary metal structures such as steel beams, bridges, and heavy machinery. The new technologies, such as electromagnetic bases, provide a secure base between the metal surface and allow both horizontal and vertical drilling. The smart sensors and brushless motors help detect slippage or loss of magnetic adhesion and are highly used in construction and offshore drilling platforms.

- Heavy Duty Tapping and Drilling Machine: We have used high-quality raw materials in these drilling machines for drilling large-diameter holes up to 50 mm. A powerful motor is installed for high-speed operations like boring, reaming, and counter boring. These heavy-duty drilling machines include automatic tool exchangers for performing multiple tasks simultaneously, making them highly useful in automotive manufacturing, aerospace, oil and gas, and large-scale machinery production.

- Bench Drilling Machines: This is our most popular drilling and tapping machine, primarily used for light-duty drilling in small workshops, laboratories, and maintenance departments. Known for its compact, lightweight design, it saves space and can create holes typically up to 13 mm in diameter. We've added a Digital Readout (DRO) that provides real-time data on operations such as drilling depth and spindle speeds. This is commonly used in prototype development and jewelry making.

- Pillar Drilling Machine: Our pillar machines are ideal for medium to large drilling operations in workshops, manufacturing units, and maintenance departments. This machine features a floor-mounted design, which is more convenient than a bench design and suitable for larger, heavier workpieces. Equipped with powerful high-speed motors, these pillar drilling machines can drill holes up to 50 mm in diameter in various materials like metal, wood, and plastic.

Technical Specifications:

For more detailed information about our drilling and tapping machines and its types, we have attached a technical sheet below:

| Specification | Magnetic Drilling Machine | Heavy Duty Tapping & Drilling Machine | Bench Drilling Machine | Pillar Drilling Machine |

|---|---|---|---|---|

| Machine Type | Portable, Magnetic Base | Stationary, Floor-Mounted | Tabletop, Light Duty | Floor-Mounted, Medium to Heavy Duty |

| Spindle Speed (RPM) | 50 - 500 RPM (Variable Speed) | 50 - 2000 RPM | 500 - 3000 RPM | 50 - 1500 RPM |

| Drilling Capacity | Up to 100 mm | Up to 50 mm | Up to 20 mm | Up to 40 mm |

| Tapping Capacity | Up to M30 | M4 to M36 | M4 to M12 | M4 to M24 |

| Power Source | Electric (AC/DC), Pneumatic | Electric, Hydraulic | Electric | Electric, Hydraulic |

| Motor Power | 1200W to 2500W | 2 to 5 HP | 0.5 to 1.5 HP | 2 to 3 HP |

| Base Size | 100 mm x 200 mm | Large, Customizable | 200 mm x 200 mm | 300 mm x 300 mm |

| Column Stroke | 0 - 300 mm | 0 - 500 mm | 0 - 200 mm | 0 - 600 mm |

| Spindle Taper | MT 2/MT 3/Custom | MT 4/MT 5 | MT 1/MT 2 | MT 2/MT 4 |

| Max. Hole Depth | 200 mm | 400 mm | 100 mm | 300 mm |

| Feed Mechanism | Manual/Automatic | Manual/Automatic | Manual | Manual/Automatic |

| Cooling System | Integrated coolant system or external reservoir | External Coolant Tank | Not common (can be external) | External Coolant Tank |

Unique features and benefits of our drilling and tapping machines:

Being the best drilling and tapping machine suppliers and exporters in Pune, our all types of drilling and tapping machine are made with new technological updates such as:

| Features | Benefits | Technological Updates |

|---|---|---|

| Variable Speed Control | Our drilling and tapping machines allow for accurate control and adjustments to match different materials and hole sizes. | Our all drilling and tapping machines come with advanced electronic speed controls, offering real-time monitoring and feedback for improving accuracy. |

| Automatic Feed Mechanism | Improves productivity and reduces operator failure. | These machines are integrated with servo motors for smoother, automated feed, and consistent drilling/tapping pressure. |

| Magnetic Base (for Magnetic Drilling Machines) | Our drilling and tapping machines enable secure attachment to metal surfaces for vertical and horizontal drilling. | It improves the magnetic clamping systems with automatic detection of uneven surfaces to ensure optimal holding force. |

| Quick-Change Tooling | This machine minimizes downtime during tool changes, improving operational efficiency. | Tool-less quick-change technology with automatic spindle locking for even faster and safer tool changeovers. |

| Depth Stop Mechanism | Our drilling and tapping machines ensure consistent hole depth and prevent over-drilling. | Our machines are made with new technological digital depth control systems, allowing operators to program exact depths with feedback on tool wear and life expectancy. |

| Smart Sensor Technology | Detects drill bit wear, improper alignment, and potential operational errors. | Integration of AI-powered sensors that predict tool failure and optimize performance based on historical usage data. |

Applications of our drilling and tapping machines:

As a leading drilling and tapping machine suppliers and exporters in Pune, these machines are majorly used in multiple applications due to their advanced functions:

- Manufacturing machinery parts and components

- Construction and building infrastructure projects

- Automotive industry assembly and repair

- Aerospace engineering and defense production

- Shipbuilding and marine equipment manufacturing

- Electrical and electronics component production

- Heavy equipment and machinery maintenance

- Oil and gas industry equipment

- Railway and locomotive manufacturing

- Medical device and equipment manufacturing

As a leading drilling and tapping machine manufacturers, suppliers and exporters in Pune, we as Technowings Automation are providing new advanced mechanism of drilling and tapping machines. We have used pure types of raw materials and updated motors for improving productivity and performance in multiple types of industries. Contact us today for more information!