Special Purpose Machine Manufacturers in Pune – Technowings Automation

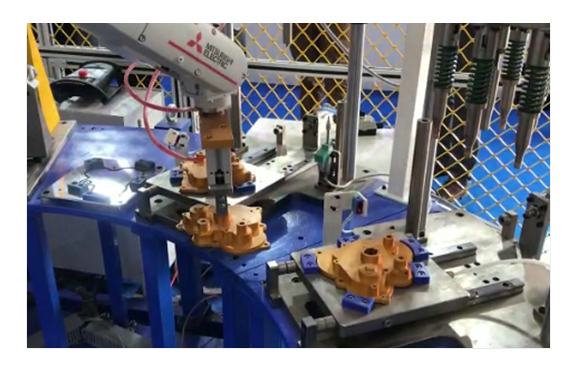

Technowings Automation, leading Special Purpose Machine (SPM) manufacturers, suppliers and exporters in Pune, is providing new technology and one of the best SPMs. These are the custom-designed machines that are built for making a specific task or set of tasks in a manufacturing process.

As per the requirements of specific industries, we manufacture these machines and install new technological updates. These machines are made with strong-quality raw materials, which give them more durability while working on major tasks, and the specialized designs can make repetitive tasks to maintain higher accuracy and speed. Let’s check out its new types, benefits and applications one by one!

What is the work of a SPM machine?

These machines are specially made and used for performing some specific tasks and help in mass production in the industrial sectors. Due to the integration of new technological updates, these machines can perform tasks more accurately, such as punching, drilling, and tapping, boring, chamfering and turning. The new and advanced SPMs do tasks such as gear-cutting and gear-grinding machines, broaching machines and honing machines.

Types of our SPM Manufacturers

As a former SPM supplier and exporter in Pune, we are providing some commonly and widely used machines with technical updates that help for improving performing major tasks. Here we have listed down some types, such as:

- Hydraulic Special Purpose Machine: These are our commonly used and high-frequency hydraulic SPMs, which use hydraulic power for performing tasks that require high force with precision. We have added new technologies such as servo-hydraulic systems that give higher force and energy savings to the machine and condition monitoring for real-time monitoring of hydraulic fluids, including temperature and viscosity. These functions can boost productivity and be used in applications such as automotive component manufacturing and the aerospace industry.

- Pneumatic Special Purpose Machine: This machine uses compressed air force for performing tasks such as packaging, labeling, and lightweight material handling. The compressed air can generate motion with higher power, making it more cost-effective than hydraulic machines. The new technological smart pneumatic actuators use position sensors that give real-time feedback for a more accurate and clear result. Additionally, wireless control technologies in these SPMs unlock remote handling and monitoring, beneficial in the food and beverage and pharmaceutical industries.

- High-Speed Special Purpose Machine: For handling major tasks and mass production in applications such as consumer goods packaging and electronics manufacturing, our high-speed special purpose machine is highly used. These are specially designed for performing repetitive tasks at extremely high speeds. We have integrated advanced robotic arms and automation systems in these machines for smoother and more complex tasks. Precision motion control also ensures high-speed movement management without failure.

- CNC-Based Special Purpose Machines: In today’s modern industrial world, CNC (Computer Numerical Control) machines are widely adopted due to their accuracy. Our CNC SPMs operate with programmed instructions to perform complex tasks such as cutting, milling, drilling, and turning with high precision. For handling intricate tasks, we have included multi-axis machining, with 5 or 7 axes, which simplifies complex geometries. These are commonly used in the medical device manufacturing and mold and die-making industries.

Technical Specifications

For more technical and detailed information about our SPMs, we have mentioned below a technical sheet which gives you a clear understating about each machine performance:

| Technical Aspect | Hydraulic SPM | Pneumatic SPM | High-Speed SPM | CNC-Based SPM |

|---|---|---|---|---|

| Power Source | Hydraulic fluid (oil under pressure) | Compressed air (pneumatic actuation) | High-power electric motors, Hydraulic/Pneumatic hybrid | Electrical power (for CNC control) |

| Actuation Method | Hydraulic cylinders, valves, motors | Pneumatic cylinders, valves | Electric motors, Servomotors | CNC-controlled servomotors, ball screws |

| Speed of Operation | Moderate, suitable for heavy-duty operations | High-speed, low resistance | Ultra-high speed (>5000 RPM for spindle operations) | Medium to High speed, depending on CNC program |

| Load Capacity | Extremely high (up to several tons) | Moderate (typically <500kg) | High (can vary depending on design, generally up to 2 tons) | High, adjustable based on part type and machine size |

| Precision | Medium (0.01mm - 0.1mm) | Low (0.1mm - 1mm) | High (0.001mm - 0.01mm) | Ultra-High Precision (±0.001mm or better) |

| Energy Efficiency | Medium (Hydraulic systems can be energy-intensive) | High (Compressed air is efficient for light tasks) | Medium to Low (depends on speed requirements) | High (Optimized for energy efficiency using intelligent control) |

| Control System | Programmable Logic Controllers (PLC) or Manual Control | PLC-based control or mechanical trigger systems | Advanced PLC, electronic cam systems, optical sensors | CNC controllers (G-Code, M-Code) with HMI/PLC integration |

| Cycle Time | Medium (depends on hydraulic pressure adjustments) | Short cycle times for small, light components | Ultra-fast cycle times (<1 second per operation for specific tasks) | Medium to Fast (depends on CNC program) |

| Force Output | Extremely High (can generate several tons of force) | Low to Medium (typically <1000N) | High (depends on design, typically high for large components) | Adjustable depending on toolpath, part geometry, and feed rate |

| Safety Mechanisms | Pressure release valves, emergency stops, mechanical locks | Air pressure safety regulators, quick exhaust valves | Advanced electronic sensors, thermal overload protection | Automated safety diagnostics, interlocks, emergency stops |

Some new technological features and benefits of using our SPMs:

As a former SPMs manufacturers and suppliers of in Pune, we have added multiple types of features in our SPMs that give you multiple benefits, such as:

- Integration of Industrial 4.0 Technologies: Our all machines are made with new technological upgrades and use smart technologies such as real-time monitoring, IoT (Internet of Things), cloud computing, and big data analysis. Due to these overall functions, our SPMs can perform any kind of major task and increase productivity. The new vibration analysis and thermal imaging can easily detect potential issues in hydraulic systems or motors.

- High-Speed Machining Technologies: All SPMs are integrated with high-speed working motors, and advanced spindles are connected to these machines for performing major tasks. The digital monitoring system helps increase productivity at higher speeds with shorter cycle times and more output. Because of these features, these are highly used in the heavy and large industrial sectors for increasing performance.

- Updated Safety Features: We have especially focused on the safety features for reducing any accidents and maintenance costs. Our machines are installed with multiple types of safety innovations, such as pressure release valves, emergency stops, and mechanical locks. In pneumatic SPMs, we have added safety functions such as air pressure safety regulators and quick exhaust valves for better handling of products. These overall safety functions are necessary for increasing performance and productivity.

- Modular and Scalable Designs: We offer our SPMs in multiple types of shapes and sizes where they can be easily upgraded and replaced. Our various machines come in compact sizes for fitting in small-scale industrial sectors, and multiple manufacturers can adopt machines to change production requirements without replacing entire systems.

Applications of our Special Purpose Machine:

Being one of the best SPM manufacturers and suppliers in Pune, our machines are used in multiple applications, such as:

- Nanostructure Fabrication and Characterization: Our SPM is used to create and analyze nanoscale structures, which provide precise control over material properties.

- Surface Topography Mapping: It provides detailed images of surface features at atomic resolution, helping researchers understand material surfaces better.

- Electrical Conductivity Measurement: Our special purpose machine can measure local electrical properties, aiding in the study of semiconductors and nanomaterials.

- Biomolecular Interactions Studies: It enables visualization and analysis of biomolecules, facilitating an understanding of biological processes at the nanoscale.

- Magnetic Properties Investigation: Our new SPM techniques are used to explore the magnetic properties of materials, which aids in improving magnetic storage devices.

As former SPMs manufacturers, suppliers and exporters in Pune, we as Technowings Automation are providing new technological special purpose machines that are highly used for simplifying major and complex industrial operations. These are made with strong and pure-quality raw materials that help increase durability and can be used in an outdoor environment. Contact us today for more information!