Drilling Cum Tapping Machine Manufacturers in Pune – Technowings Automation

Technowings Automation is one of the former drilling cum tapping machine manufacturers, suppliers and exporters in Pune. We are providing one of the best drilling and tapping machines that are made with pure quality raw materials such as stainless steel and cast iron.

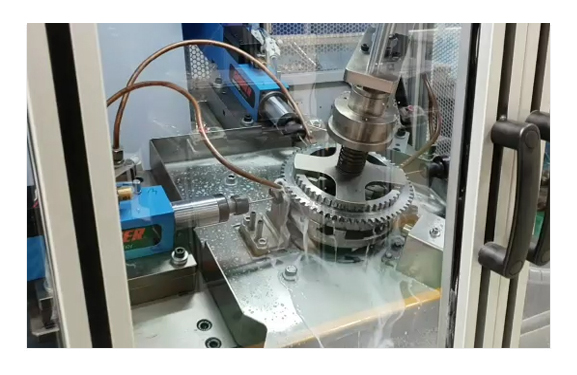

This machine is highly versatile and used for both drilling cum tapping operations simultaneously, and we have added new technological updates to these machines, such as automatic reversal, an emergency reversing foot switch, and heat rotation options. Due to this upgrade, these are highly applicable in automotive component manufacturing, metal fabrication and sheet metal work.

Types of our Drilling Cum Tapping Machine Manufacturers:

As a former drilling and tapping machine supplier and exporter in Pune, we are providing a wide range of machines that are made with new features and applied to many applications. Here we have listed down some types, such as:

- Magnetic Drilling Tapping Machines: These machines have a strong magnetic base and are used for drilling and tapping and are also able to handle thick steel plates, I-beams, and other ferrous materials. We have included the new integrated overload protection for handling a large amount of load, and the new digital RPM control simplifies overall work with easy handling. These are primarily used in construction and fabrication.

- Automatic Drilling Cum Tapping Machine: As per the evolution of new modern technologies, we are offering the new automatic drilling cum tapping machine, which works under full automation and now comes with CNC (Computer Numerical Control) machines. These are usually used for continuous operations and can handle thick metal sheets for drilling. The new servo motors help with handling major loads and improve speed and torque.

- Mild Steel Drilling Tapping Machines: Our new technological mild steel drilling tapping machine comes with a new automatic feeding system that detects any kind of steel material and accurately makes holes. The advanced cooling system helps reduce excessive heat in the machine and increases performance. It can handle mild steel sheets, beams, and tubes.

- Portable Pneumatic Drilling and Tapping Machine: Compared to all kinds of drilling machines, this machine has higher pressure and force for performing major tasks. It uses compressed air, making it explosion-proof and safe for hazardous materials such as oil refineries or chemical plants. Our modern types of models have variable speed control mechanisms that give easy handling of the overall process and are used in pipeline construction and structural steel installations.

Technical Specifications:

We have added a technical sheet below for more reference about our drilling cum tapping machine:

| Specification | Magnetic Drilling Tapping Machines | Automatic Drilling Cum Tapping Machine | Mild Steel Drilling Cum Tapping Machines | Portable Pneumatic Drilling Cum Tapping Machine |

|---|---|---|---|---|

| Power Source | Electric motor with magnetic base (AC-powered) | CNC with Electric Servo Motors | Electric motor (AC-powered) | Compressed air |

| Drilling Capacity | Up to 50 mm | 1 mm to 50 mm, adjustable with CNC programming | 12 mm to 32 mm, depending on machine size | 10 mm to 25 mm, varies based on air pressure |

| Tapping Capacity | M6 to M30, capable of handling large taps | M3 to M36, controlled via CNC for accuracy | M5 to M20 | M4 to M18, ideal for field applications |

| Spindle Speed | Variable (50–600 RPM) with digital control | 100–5000 RPM, programmable using CNC | 300–3000 RPM, manually adjustable | 100–2000 RPM, controlled by air pressure regulation |

| Magnetic Holding Force | 1500–2500 kgf for secure clamping on ferrous surfaces | Not applicable | Not applicable | Not applicable |

| Automatic Tool Changer | Not available | Yes, integrated automatic tool changer for rapid switching between drilling and tapping | No | No |

| Feed Type | Manual or automatic feed, with pressure control | Fully automatic, controlled via CNC programming | Manual or semi-automatic feed with depth stop | Pneumatic feed, controlled by valve switch |

| Advanced Cooling System | Automatic cooling with internal coolant channel for extended tool life | Integrated cooling system with programmable flow rate | External coolant system or mist-based lubrication | Air-based cooling or optional external coolant attachment |

Features and Benefits of Using Our Drilling and Tapping Machine:

Being one of the best drilling cum tapping machine suppliers and exporters in Pune, these machines are fully equipped with new updated features such as:

- Variable Speed Control: All machines come with new advanced high-speed spindle technology and adjustable feed rates. This technology provides accurate drilling over any metal sheet or surface. Due to these qualities, it can increase performance and offer better control over soft materials such as aluminum.

- Automatic Tool Changer: Our automatic drilling and tapping machines are installed with an automatic tool-changing mechanism that is more helpful for switching between different drill and tap tools without manual intervention. This function is particularly useful in large and high-volume production lines.

- Digital RPM Display and Control: For smoother handling of the machine and easy controlling, we have added a new digital RPM display. This display features a touchscreen option and can control overall machine adjustments. This feature helps increase productivity and ensures accurate adjustment during operation.

- Overload Protection System: We have used strong and high-quality raw materials in all types of drilling and tapping machines, enabling them to handle significant loads without failure. In the event of an overload, the machine automatically stops, preventing any motor damage and tool breakage. This feature helps reduce maintenance costs and increases the life of the machine.

Applications of our drilling and tapping machine:

As a leading drilling cum tapping machine manufacturer and supplier in Pune, all types of machines are loaded with multiple amounts of features and used in multiple applications, such as:

- Automotive Component Manufacturing: Our various types of drilling and tapping machines are used to create accurate holes and threads for engine blocks, gearboxes, and other automotive parts.

- Aerospace Industry Machining: This machine can perform high-precision drilling and tapping for aerospace parts like turbine blades and structural components.

- Electrical and Electronic Enclosures: This machine can easily drill and tap holes for mounting electronic components and connectors in enclosures.

- Furniture Manufacturing: It creates screw holes and threaded joints for assembling wooden and metal furniture.

- Pipe and Plumbing Fixtures: Our drilling and tapping machine can tap threads for pipe fittings and plumbing components.

- Metal Fabrication and Sheet Metal Work: Drills and taps holes in sheet metal parts for assembly in various structures like frames, panels, and housings.

Being one of the dominant drilling cum tapping machine manufacturers, suppliers and exporters in Pune, we at Technowings Automation are providing the best quality drilling cum tapping machine that is made with new technological updates. The multiple types of features in these machines help increase performance and productivity in large and heavy industries. For more information, contact us today!